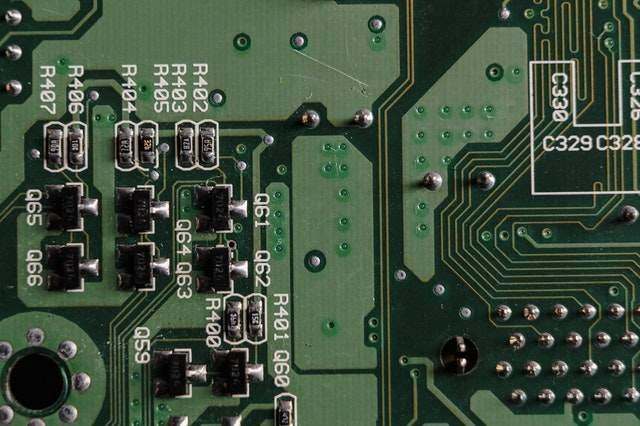

When you hear the words “printed circuit board (PCBs),” what comes to mind? Someone will confuse it with a microcircuit, and someone will grasp what it is about, but it will most likely be described as “a greenish plate with various radio components strung on it.”

On the Internet, there are numerous explanations and responses to the issue posed in the title. However, many of them turn out to be little more than guesses or assumptions. To grasp the situation, here TopicFlix advise using logic, facts, and history.

HISTORY OF PCBs (PRINTED CIRCUIT BOARD)

The very first printed circuit boards (PCBs) appeared at the turn of the century, and they didn’t look anything like what we’re used to seeing now. Boards did not begin to take on a characteristic appearance until the 1920s, when they were utilized in gramophones and tube receivers.

Various resins began to be employed for printed circuit boards in the mid-nineteenth century, primarily in the military and communications sectors. We used a yellow-brown epoxy with identical hardeners.

As a result, the printed circuit boards (PCBs) had a dingy, unappealing color. Something along the lines of the image below. When we disassemble an outdated technology, we can uncover exactly such boards that were common at the time.

They attempted adding various coloring components to make printed circuit boards more aesthetically beautiful, but this just made things worse.

As a conclusion, the desired color could not be achieved. Later, a printed circuit board (PCBs) mask appeared, which was simply green in color. Manufacturers modified it by adding other dyes until they achieved the desired color, which has since become the industry standard in most printed circuit boards (PCBs) .

Because it was easier to produce printed circuit boards that were perfectly green at the time, it gained traction in the industry and became standard. As a result, many current electronics makers employ this color.

THERE ARE OTHER REASONS, TOO

Printed circuit boards (PCBs) are made of fiberglass, and their color is determined by the solder mask that is placed, which, as we mentioned earlier, is more frequent in green. The solder mask shields the conductive pattern from impurities and the effects of the environment.

- When done by humans in manufacturing, the green solder mask on PCBs became more acceptable for quality monitoring. Green was more appealing to the workers’ eyes and less tiresome to look at.

- The green solder mask color on printed circuit boards (PCBs) has become standard. The green hue of the solder mask has become the cheapest to produce as a result of its widespread use, and this is typically a deciding factor.

- Modern computer equipment for printed circuit board quality control can be customized for green color.

IN SUMMARY

Printed circuit boards (PCBs) of a specific hue are no longer required in modern technology. People are almost never involved in the creation or control of these machines; everything is done by robots.

Green is no longer a suitable hue for printed circuit boards, and it will most certainly become obsolete.

Still, the most important aspect is that the electronics are dependable and last a long time, gratifying the consumer.

Article Powered by TOPICFLIX

About the Author

Manish love to write and he is a Civil Servant. Users can follow Manish on Instagram ![]()